FAQ

As a Printed Circuit Board supplier, we receive many technical questions regarding PCB fabrication.

Here you can find our FAQ about PCBs. If you can't find an answer to your question, please, contact the office near you so we can assist with your needs.

Gerber file or ODB++ and customer specification/technical data sheet.

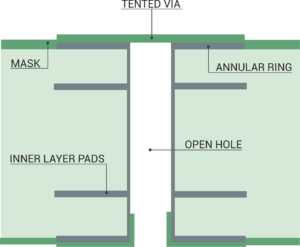

Tenting in PCB means covering the annular ring via a hole with a solder mask. Tented Vias are those that are completely covered with a solder mask.

Via tenting is performed to reduce the number of exposed conductive pads on a PCB.This mitigates the probability of physical damage like corrosion and shorts happening due to solder bridging.

You can find our capabilities for Rigid, Flex Rigid, HDI and Flexible PCBs here in the following link: Capabilities

When you fill the specifications in your RFQ, you should specify:

- Layer Count

- Surface Treatment

- Board Size

- Panel Size

- Boards/Pni

- Material

- Board Thickness

- Solder Mask Color

- Legend Print

- Production Specification

- Other important specification, if it's needed.

Materials are different. Tented Vias use dry film solder mask, Plugging Vias use liquid solder mask or resin. Also, Plugging Vias allows partial material penetrate into the via, but Tented Vias just need to bridge over vias wherein no additional materials are in the hole.

FR4 is the most common material grade that used for fabricated circuit boards. ‘FR’ indicates the material is flame retardant and the ‘4’ indicates woven glass reinforced epoxy resin

CEM-1 is low-cost, flame-retardant, cellulose-paper-based laminate with only one layer of woven glass fabric.

CEM-2 has cellulose paper core and woven glass fabric surface.

CEM-3 is very similar to the most commonly used PCB material, FR-4.

IPC 4101E define thermal conductivity level for aluminum PCB as below:

Level A ≤1.0

Level B >1.0 ≤2.0

Level C >2.0 ≤3.0

Level D >3.0 ≤5.0

Level X AABUS

| IPC-4101 | 99 | 101 | 121 | 124 | 126 | 127 | 128 | 129 | 130 |

| Tg (min) C | 150 | 110 | 110 | 150 | 170 | 110 | 150 | 170 | 170 |

| Td (min) C | 325 | 310 | 310 | 325 | 340 | 310 | 325 | 340 | 340 |

| CTE Z 50-260 C | 3,5% | 4% | 4% | 3,50% | 3% | 4% | 3,50% | 3,50% | 3% |

| T260 (min) minutes | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| T288 (min) minutes | 5 | 5 | 5 | 5 | 15 | 5 | 5 | 15 | 15 |

| Fillers > 5% | Yes | Yes | NA | NA | Yes | Yes | Yes | NA | Yes |

| Dk/Permittivity (max) | 5,4 | 5,4 | 5,4 | 5,4 | 5,4 | 5,4 | 5,4 | 5,4 | 5,4 |

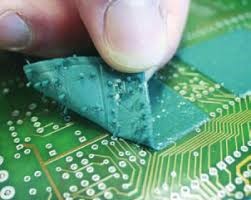

The "peelable solder mask" it's a liquid and (also known as strippable mask or blue-mask) is applied by screen-printing, act as in-process protection and are removed after processing at the assembler.

It provides printed circuit boards with protection in soldering processes like wave soldering, selective soldering or at the PCB level a surface finish protection.

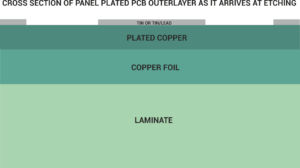

Initial copper means base copper which come from the laminate we buy. Final copper means the copper thickness for the finished PCB , it include base copper and plating copper.

Yes, our factory comply with RoHS Directive.

RoHS stands for Restriction of Certain Hazardous Substances. It is an European legislation that bans six hazardous substances from manufacturing processes: cadmium (Cd), mercury (Hg), hexavalent chromium (Cr (VI)), polybrominated biphenyls (PBBs), polybrominated diphenyl ethers (PBDEs) and lead (Pb).

PCB shelf life were defined based on PCB surface finishes, IPC define PCB shelf life as below:

HASL - 12 months

HASL lead free - 12 months

ENIG - 12months

ENEPIG - 12months

Immersion Silver - 6 months

Immersion Tin - 6 months

OSP - 6 months

Mouse bite holes are designed in panel for facilitating separate PCB from frame, it is normally design in two rows.

V-cut is also called V-Scoring, it is used for mechanical pre-separation of circuit boards.

V-cut can only be performed along straight line, A V-shaped breaking line is formed in the circuit board with a precision cutting tool.

Performing V-cut is just for PCB separation become easily.

FR4 is the most popular type of material in the PCB manufacturing. FR4 material is ideal to produce one layer PCB or multilayer PCB. It suits for demands for flexible or rigid PCBs as well.

Multilayer PCB is a printed circuit board that has more than, at least, four layers, with one or multiple conductor patterns inside the board. You can see our Multilayer Capability

The HDI - High Density Interconnector PCBs have a higher wiring density compared with standard PCBs. Check our HDI Sheet Capability

Flexible printed circuit boards are boards that uses flexible based material in your applications. They can be single or double sided up to 6 layers. You can check our Flex Capability